Spark Arrestors: Useful Fire Safety Devices

Last year, following the disastrous Gatlinburg, Tennessee wildfires, I offered a blog about upgrading your neighborhood fire safety, with an emphasis on it being a year-round maintenance goal: Town and County Tips on Fire Protection. Since then, the California wine country wildfires – at least a dozen – killed at least 42 people and destroyed an estimated 8,000 homes.

So today, continuing that theme, let us consider spark arrestors. These are simple metal screens, which fit over chimney tops above wood-burning stoves, fireplaces, and furnaces. Burning wood, paper, and cardboard often throws off glowing embers and sparks, which can get drafted up the chimney with the smoke, and then drift away still glowing, and can ignite fires nearby. If your house happens to have a wood shake or split cedar shingle roof, and it has been very dry for a few weeks, it is possible to even set your own roof on fire. Tarpaper shingle roofing has a thin layer of rock granules built into the outer surface to prevent this from happening (there is a standardized lab test for this in which a precise little fire of pine slats are stacked a certain way and burned to see whether tarpaper roofing samples ignite: see ASTM E108-17 for details). Sheet metal roofs are not flammable from sparks.

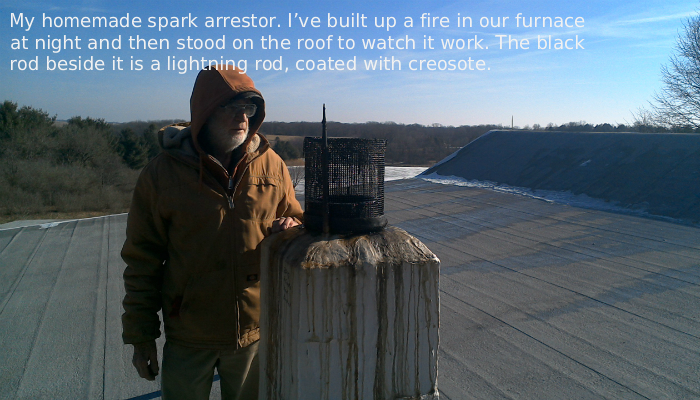

Close up of spark arrestor, tacky with creosote from last night’s fire.

The actual spark arrestor is a metal mesh basket, which is mostly holes in order to not interfere with the smoke rising, but the larger sparks and embers will hit the mesh. This helps in several ways. The embers have no strength, being a floating, glowing carbon film, easily broken apart by hitting the mesh, with the little pieces cooling quickly, usually within a second or two, well before they can land on anything. The metal is also a good conductor of heat and a spark that momentarily lodges on the screen gets its heat sucked away and goes dead.

Some spark arrestors have caps on top to shed rain from going down the chimney. All of them also keep birds from falling in and getting trapped. My own spark arrestor has always been a simple one made by wrapping quarter-inch hardware cloth into a cylinder and capping it with the same mesh. It is anchored against strong winds by a lead collar wrapped around the bottom. The mesh lasts four or five years before it begins to unravel and I must replace it, while the lead collar is my original from 1976 and just gets transferred to new arrestors.

When in use regularly during winter the mesh gets tacky with a thin layer of black creosote. But over the summer this dries and becomes flakey, and is readily removed during maintenance by tapping with a little stick.

Commercial spark arrestors are available in several configurations and made from several materials. If you purchase one, make sure that it has provisions for removal during chimney cleaning, and that it will not blow off accidently during storms.

So if you burn wood, consider making or buying a spark arrestor for your chimney and making your neighborhood a little less vulnerable to fire.